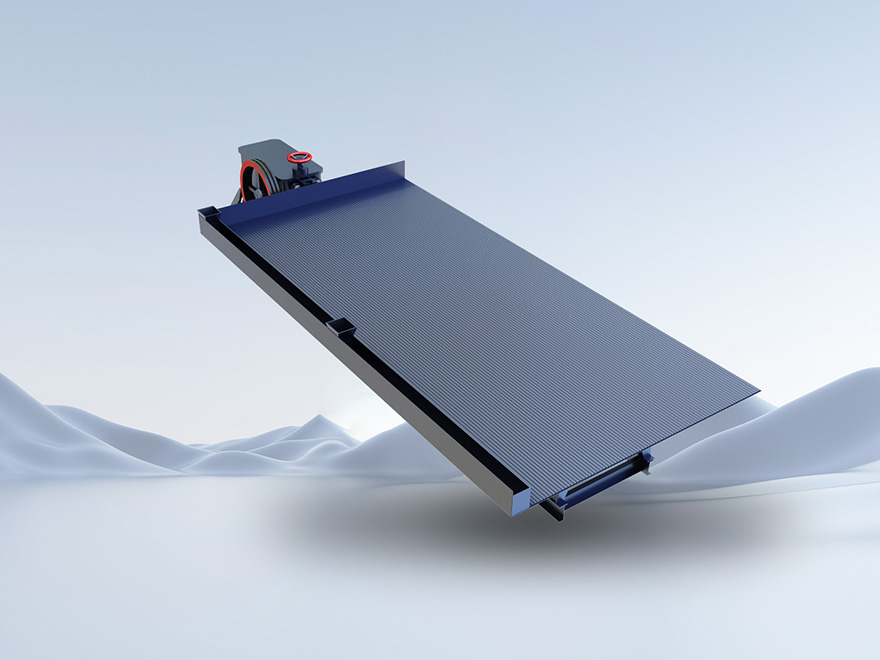

A Shaking Table are basically low-capacity machines used as last step in the gold upgrading process. The shaking table is a thin film, shear flow process equipment, that separates particle grains of its feed material based on the differences in their specific gravity, density, size and shape.

Applied material: tin, tungsten, gold, silver, lead, zinc, tantalum, niobium, titanium, manganese, iron ore, coal, etc

Send E-mail:market@hxjq.com

The shaking table is widely used in the selection of tin, tungsten, gold, silver, lead, zinc, tantalum, niobium, iron, manganese, limonite and coal. Our company has the long history of making table concentrator and gold shaker table, and we also continue to research independently on the technology and mechanism of the mining machine on the basis of the origin liner table concentrator.

1. Carry out to detect bed ministries complying with the requirements of the drawings, parts

2. Lifting bed of the gold shaker table installed in front of the connector and four connected blocks

3. Hammock should prevent the local compression deformation of the side plates and shall collision bed

4. Bed installation, each connected to the screw holes should be aligned

5. Each bond inspection is correctly installed, the empty running 1-2 hours

6. Empty running is completed

.jpg)

| Name | Grit concentrator table |

Fine sand concentrator table |

Sludge concentrator table |

|

| Bed surface Dimensions |

Length (mm) |

4450 | 4450 | 4450 |

| Driving part Width (mm) |

1855 | 1855 | 1855 | |

| Concentrate part Width (mm) |

1546 | 1546 | 1546 | |

| Max.feeding size(mm) |

2 | 0.5 | 0.15 | |

| Feeding amount (t/d) |

30-60 | 10-20 | 15-25 | |

| Feeding thickness (%) |

25-30 | 20-25 | 15-25 | |

| Stroke (mm) |

16-22 | 11-16 | 8-16 | |

| Frequency (f) |

45-48 | 48-53 | 50-57 | |

| Bed surface Water quantity (t/d) |

80-150 | 30-60 | 10-17 | |

| Bed surface Horizontal obliquity(°) |

2.5-4.5 | 1.5-3.5 | 1-2 | |

| Bed surface Portrait obliquity(%) |

1.4 | 0.92 | ---- | |

| Table board corner(°) |

32-42 | 40 | 42 | |

| Concentrating area(㎡) |

7.6 | 7.6 | 7.6 | |

| Bed surface Length ratio |

2.6 | 2.6 | 2.6 | |

| Shape of side-bed surface |

Rectangle | Zigzag | Triangle | |

| Motor power(kw) |

1.1 | 1.1 | 1.1 | |

| Transmission device |

Eccentricity Linkage | |||

Name: Mining-Mineral-Ore-Machine

For: share openings, doing business, make information transmission

Click it to Join in