Processing ability: 0.2~8 m³/min

Dressing methods: Flotation separation plant, Magnetic separation plant, Gravity separation plant

Material handling: copper, zinc, lead, nickel, gold, Manganese ore,tungsten ore, tin ore, mercury ore,titanium ore, lead ore, titanium niobium ore, galena ore, celestite, barite, fluorspar, pyritic,limonite, hematite, antimony ore, chrome ore,etc.

Send E-mail:market@hxjq.com

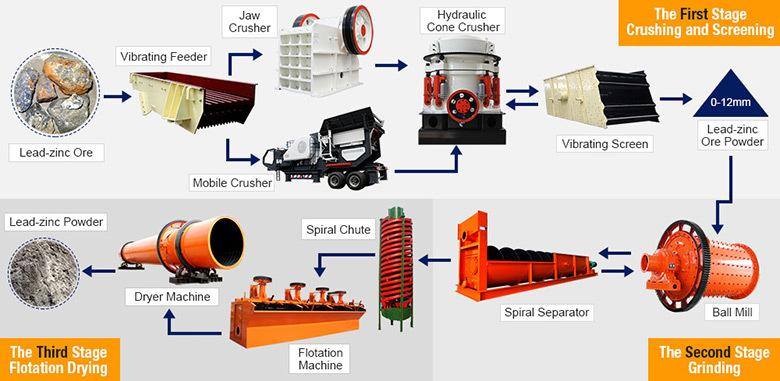

Ore Beneficiation plant is classified into three kinds: flotation separation, magnetic separation and gravity separation. It generally includes the following parts like crushing, milling and separating, etc.

Jaw crusher can primarily crush the large ores, which are just digged out.

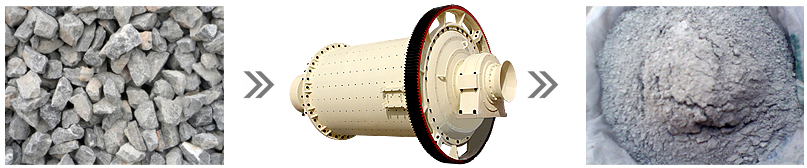

Ball mill plays the role of grinding crushed ores and grinding work is the base for separation. HXJQ ball mill is the upgraded version of traditional mills and it is specially used for ore grinding.

Flotation cell is used in flotation separation plant and it can make the complete integration and reaction between ore powders and drugs.

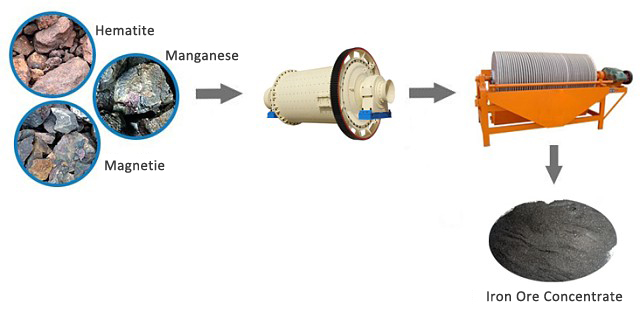

Magnetic separator is used in magnetic separation plant and it is suitable to process the ores which contain iron content inside like magnetite, pyrrhotite, roasted ore, ilmenite, etc.

Gravity chute and shaking table are used in gravity separation plant. They are suitable for separating 0.3--0.02 mm size fine minerals such as iron ore, titanium ore, chrome ore, etc

If you want to dry the concentrates effectively and rapidly, the Industrial dryer will be the best choice. It can save energy for more than 60%.

Name: Mining-Mineral-Ore-Machine

For: share openings, doing business, make information transmission

Click it to Join in