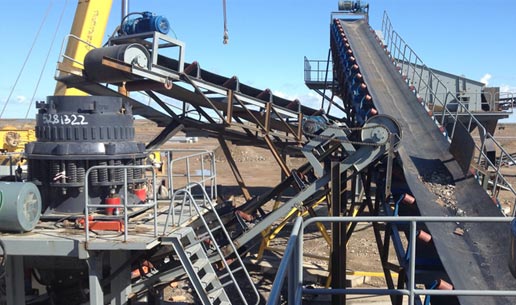

Production Capacity: 50-800t/h

Application Ranges: mineral mining, building material, bridges, high-ways, road, construction, chemical, metallurgy, coal mining and so on.

Applied Materials: Granite, basalt, bank gravel, coal, bauxite, cement clinker, quartz silicon carbide,limestone, river stone, etc.

Production Capacity: 50-520t/h

Finished Size: 0-5mm

Applied Materials: Granite, basalt, bank gravel, bauxite, cement clinker, quartz silicon carbide,limestone, river stone, etc

Common Configuration: Vibrating feeder, jaw crusher, impact crusher, vibrating screen, sand maker, sand washer and centralized electric control

Production Capacity: 0.5-30t/h

Discharging Size: 80-12,000mesh

It can be used for processing Feldspar, calcite, talc, barite, fluorite, rare earth, marble, ceramics, bauxite, manganese ore, phosphate ore, iron oxide red, quartz sand, cement clinker, activated carbon, clay, coal gangue, gypsum, silicon carbide, refractory material, etc

It can be used for processing Feldspar, calcite, talc, barite, fluorite, rare earth, marble, ceramics, bauxite, manganese ore

Processing ability: 0.2~8 m³/min

Dressing methods: Flotation separation plant, Magnetic separation plant, Gravity separation plant

Material handling: copper, zinc, lead, nickel, gold, Manganese ore,tungsten ore, tin ore, mercury ore,titanium ore, lead ore, titanium niobium ore, galena ore, celestite, barite, fluorspar, pyritic,limonite, hematite, antimony ore, chrome ore,etc.

Production Capacity:0.18-7(m³/min)

This ore beneficiation production line is mainly composed of jaw crusher, ball mill, spiral classifier, mixer, flotation machine, ore concentrator and dryer machine

Production Capacity:10-280t/h

Application Ranges:calcined ore and ilmenite

beneficiation production line is mainly composed of jaw crusher, ball mill, spiral classifier

Production Capacity:25-195t/h

Feeding Granularity:≤25mm

thus greatly improving the output of cement mill and reducing the energy consumption.

Discharging size: 325-1800 mesh

Applied material: Barite, calcite, feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, gypsum, iron oxide red, slag, grain slag, clinker, insulation materials, etc.

Production Capacity: 200-8000t/d

Technical Advantages:highly efficient, high quality

thus greatly improving the output of cement mill and reducing the energy consumption.

Production Capacity:150-600t/d

Specification of Rotary Kiln:Φ2.5×40~Φ4.8x68m

The qualified limestone is store in the material cabin, elevated by the bucket elevator

The area coverage is 20-30 square meters and whole plant needs 3 or 5 people for operation and maintenance. Besides, if necessary, it can become semi-automatic.