Primary advantages of HX vibrating screen is Lubrication by thin oil, replace the lubricant in 3-6 months

Application ranges: Salt & Sugar, Sand & Gravel, Granular Materials, Ceramics, Pellets, Crushed Stone, Minerals, etc

Send E-mail:market@hxjq.com

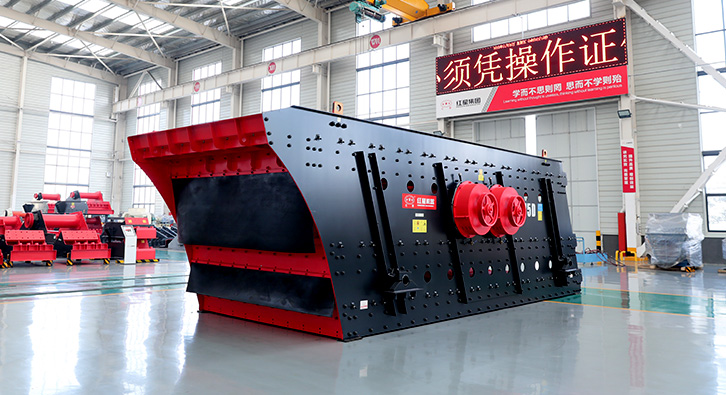

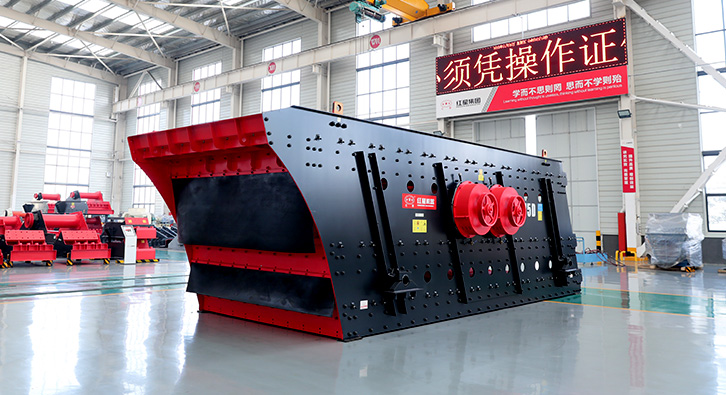

Circular vibrating screen is a kind of doing a circular vibrating, numerous layers and high efficiency vibrating screen. Round vibrating screen takes a cylinder type eccentric shaft vibration exciter and partial block to adjust the amplitude, material sieve drip line, which has the advantage of reliable structure, strong exciting force, high screen efficiency, low noise, durable usage, easy maintenance and security for the mining operator and which also can be used in the classifying of the products such as mining, building material, transportation, energy saving and chemical industry.

1. Strong vibration of the screen box, can reduce the material clogging the sieve, sieve has high screening efficiency and productivity.

2. Structure is simple and convenient, which is easy to replaceable screen surface.

1. Circular vibrating screen adopts cylinder eccentric shaft vibration exciter and partial block to adjust the amplitude, and easy maintenance.

2. Circular vibrating screen spring steel woven mesh or punching sieve, long service life, is not easy to stop up the hole.

3. Circular vibrating screen with rubber isolation spring, long life, low noise, and smooth over the resonance region.

It is mainly composed of screen box, exciter, suspension (or support) device and motor. The electric motor through V-belt driven exciter Spindle, due to the unbalanced centrifugal force of inertia of the weights on the exciter, screen box were vibrating. Change the exciter eccentric weight, obtain different amplitude.

| Model | Sieve Layer | Sieve Area (㎡) |

Mesh Size (mm) |

Max.Feeding Size (mm) |

Processing capacity (m³/h) |

Vibrating Frequency (r/min) |

Double Amplitude (mm) |

Power (kw) |

Sieve Obliquity (°) |

Sieve Specification (mm) |

Dimensions (L×W×H) (mm) |

| 2YK1230 | 2 | 7.2 | 4-50 | 200 | 12-78 | 970 | 6 | 6P 7.5 | 20 | 1200×3000 | 3530×1885×920 |

| 3YK1230 | 3 | 10.8 | 4-50 | 200 | 13-80 | 970 | 6 | 6P 7.5 | 20 | 1200×3000 | 3675×1885×1320 |

| 2YK1237 | 2 | 8.88 | 4-50 | 200 | 15-86 | 970 | 6 | 6P 7.5 | 20 | 1200×3700 | 4230×1990×920 |

| 3YK1237 | 3 | 13.32 | 4-50 | 200 | 16-90 | 970 | 6 | 6P 7.5 | 20 | 1200×3700 | 4375×1990×1320 |

| 2YK1548 | 2 | 14.4 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 11 | 20 | 1500×4800 | 5355×2195×1030 |

| 3YK1548 | 3 | 21.6 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 15 | 20 | 1500×4800 | 6055×2195×1740 |

| 4YK1548 | 4 | 28.8 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 18.5 | 20 | 1500×4800 | 6195×2195×2120 |

| 2YK1854 | 2 | 19.44 | 5-80 | 200 | 32-312 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6515×2555×1370 |

| 3YK1854 | 3 | 29.16 | 5-80 | 200 | 32-312 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6655×2555×1750 |

| 4YK1854 | 4 | 38.88 | 5-80 | 200 | 32-336 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6790×2555×2130 |

| 2YK2160 | 2 | 25.2 | 5-100 | 200 | 50-475 | 970 | 6 | 6P 30 | 20 | 2100×6000 | 7200×2945×1580 |

| 3YK2160 | 3 | 37.8 | 5-100 | 200 | 50-475 | 970 | 6 | 6P 30 | 20 | 2100×6000 | 7340×2945×1980 |

| 4YK2160 | 4 | 50.4 | 5-100 | 200 | 50-497 | 970 | 6 | 6P 37 | 20 | 2100×6000 | 7490×2945×2380 |

| 2YK2460 | 2 | 28.8 | 5-100 | 200 | 65-550 | 970 | 6 | 6P 30 | 20 | 2400×6000 | 7200×3200×1580 |

| 3YK2460 | 3 | 43.2 | 5-100 | 200 | 70-620 | 970 | 6 | 6P 37 | 20 | 2400×6000 | 7340×3200×1980 |

| 4YK2460 | 4 | 57.6 | 5-100 | 200 | 80-680 | 970 | 6 | 6P 45 | 20 | 2400×6000 | 7490×3200×2380 |

| 2YK2866 | 2 | 31 | 5-100 | 200 | 70-650 | 970 | 6 | 6P 37 | 20 | 2800×5600 | 6950×3610×1790 |

| 3YK2866 | 3 | 47 | 5-100 | 200 | 80-700 | 970 | 6 | 6P 45 | 20 | 2800×5600 | 7130×3610×2270 |

| 4YK2866 | 4 | 62 | 5-100 | 200 | 90-750 | 970 | 6 | 6P 55 | 20 | 2800×5600 | 7300×3610×2750 |

| 2YK2873 | 2 | 39.2 | 5-100 | 200 | 70-680 | 970 | 6 | 6P 37 | 20 | 2800×6500 | 7850×3587×1790 |

| 3YK2873 | 3 | 58.8 | 5-100 | 200 | 80-720 | 970 | 6 | 6P 45 | 20 | 2800×6500 | 8025×3587×2270 |

| 4YK2873 | 4 | 58.8 | 5-100 | 200 | 90-950 | 970 | 6 | 6P 55 | 20 | 2800×6500 | 8200×3587×2750 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Name: Mining-Mineral-Ore-Machine

For: share openings, doing business, make information transmission

Click it to Join in