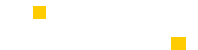

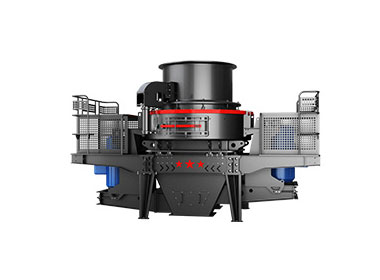

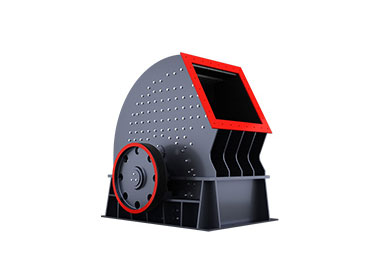

The large stone is evenly fed by a vibrating feeder into the jaw crusher for coarse crushing, the coarse crushed rock is sent to the impact crusher (or cone crusher) for further crushing, and finally the fine crushed rock is sent to the vibrating screen for screening. Stones that meet the particle size requirements are sent to the finished product stockpile, and those that do not meet the particle size requirements are returned for further crushing.

The final size of the finished product can be adjusted according to the customer's requirements.